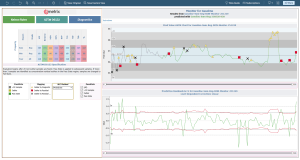

In the petroleum industry, this approach is applied at scale. Facilities often monitor dozens or even hundreds of predictive models simultaneously, such as summer, winter, and all-season fuel grades. In this example, 27 models (a 9×3 grid) are tracked, though some refineries monitor more than 300. The system works with any optical instrument and with any chemometrics assessment software.

In the petroleum industry, this approach is applied at scale. Facilities often monitor dozens or even hundreds of predictive models simultaneously, such as summer, winter, and all-season fuel grades. In this example, 27 models (a 9×3 grid) are tracked, though some refineries monitor more than 300. The system works with any optical instrument and with any chemometrics assessment software.

ASTM D6122 provides sample-specific guidelines for evaluating these models. Rather than relying on simple fixed limits, it defines dynamic, sample-specific thresholds. When samples fall outside these limits, Ai-Metrix can kick in to supply an updated model in minutes.

Different visual indicators convey different issues:

- Yellow triangles represent samples that are statistically in control but unusual for the model. These are often good candidates for inclusion to improve model robustness.

- Red squares indicate that model diagnostics are acceptable, but the predicted value does not match laboratory results—typically signaling a laboratory error.

- X markers show both diagnostic failures and unusual samples, indicating a true system failure that requires intervention.

Although the ASTM calculations are complex, they are well-suited for automated computation. Once implemented, users can quickly drill into individual samples to examine diagnostics, model predictions, and laboratory values. This allows identification of discrepancies where the system is stable, but results are out of specification, often revealing process or lab issues rather than model faults.

By compressing large volumes of historical data into actionable metrics and applying these models in real time, organizations can distinguish false positives, detect procedural problems, and better understand the sources of disagreement between manufacturing and laboratory measurements.

ASTM’s work is notable because it formally codifies how to evaluate model performance—something that had not been standardized before. While adoption has been strongest in refining, these methods are largely unknown in pharmaceuticals, chemicals, and food manufacturing.

With real-time feedback and rapid model updates, these systems enable smarter, more adaptive manufacturing. This is where machine learning and AI naturally fit: not as replacements, but as practical overlays that enhance existing workflows and produce outputs that can support regulatory discussions.

Learn more about Ai-Metrix automation. Contact us at info@infometrix.com for a demo.